FRP cable tray and fittings design and made by NHÀ CÁI CASINO UY TÍN SỐ 1 CHÂU Á with high-quality, conforms to the requirements technical standard, application for all construction on shore, off shore & harsh environment.

In the electrical wiring of structures, a cable tray system is utilized to help protect electrical cables utilized for power dissemination, control, and telecommunications.

FRP (Fiber-reinforced plastic) is a composite material made up of polymer that is supported with fibers for added strength.

FRP structural fiberglass has the strength of steel at a fraction of the weigh, it won’t corrode, rot, conduct electricity. It can be formed into countless FRP profiles to fit your specs.

FRP cable tray production by Pultrusion process, it is a continuous, automated process that is cost-effective with high production standard.

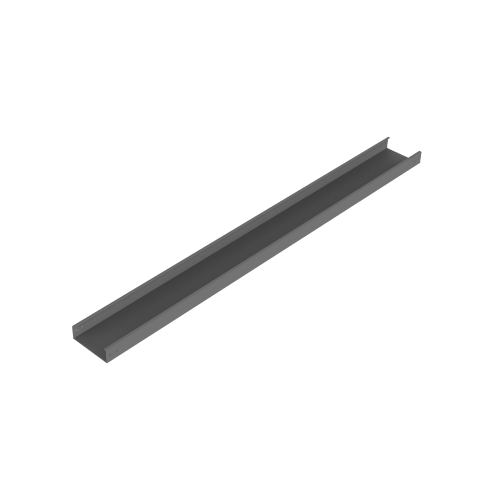

Cable tray is structure consisting of a bottom and side rails.

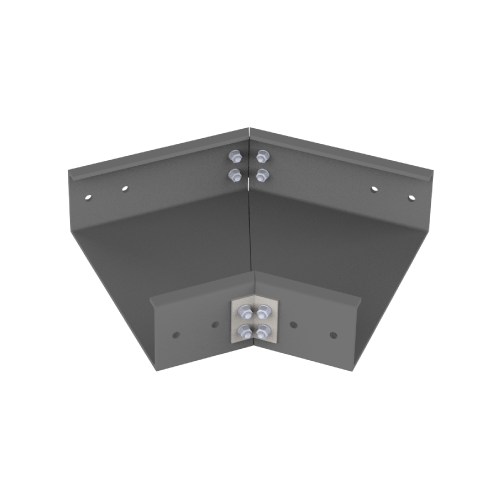

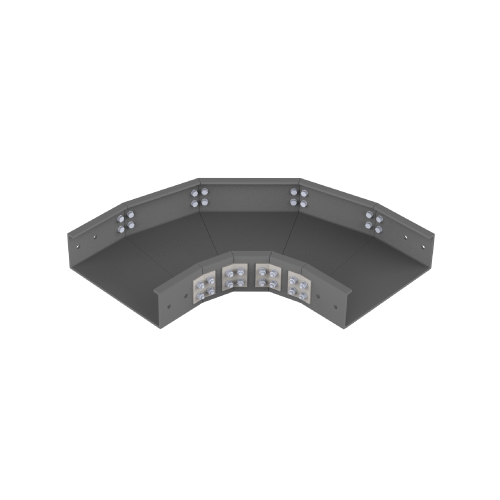

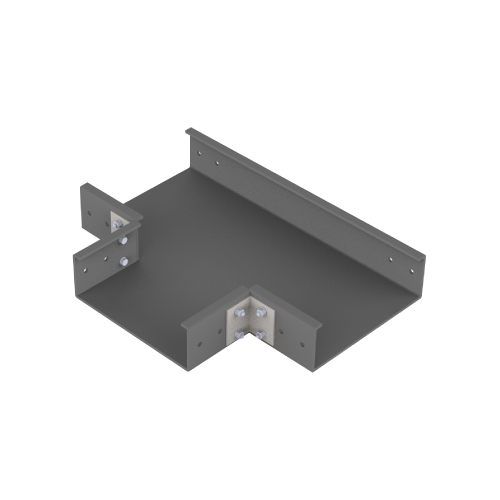

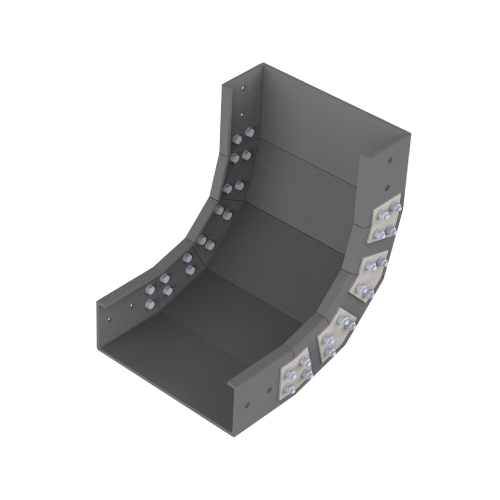

Cable Tray System contains many sorts of straight lengths furthermore as different formed fittings planned to work with adjusting cabling direction or levels viably, without the need to switch any parts.

Advantage:

- Resistance to chemicals, acid fumes, fire, rust and different corrosives

- Save installation labour and material costs

- Need less upkeep over time

- Long life span

- Cable trays are the most aesthetically pleasing option

- Lightweight, Flexible, easy and quick installation

- Save space

- Optimal burden bearing

- Prevents cables from drooping

- System’s fitting such as elbows, tee, cross and riser… make it easy to change direction or level of the cable tray

Appilication: On shore, Off Shore, Marine, Heavy industrial, Oil & gas,…

Flyer

Flyer More Documents

More Documents